PROJECT SOLUTIONS

- Home

- Pages

PROJECT SOLUTIONS

Statement of Work

Managing contracts, suppliers, quality, and delivery of work can be a tedious process. At Cube Hub, we offer Statement of Work (SOW) management services that aim to eliminate risk and augment returns by contractually defining the project scope, objectives, timelines, KPIs, and deliverables.

Time & Material

Time & Material contracts provide opportunities for Cube Hub for acquiring services on the basis of Direct labor hours at specified fixed hourly rates that include wages, overhead, general and administrative expenses, and benefits. The most significant advantage of Time and Material contracts is their flexibility and achieving KPIs. Time and material contracts are simple to make and extend and easy to end. That makes it possible to quickly or efficiently scale up and down in resources as needs and demand change.

Fixed Price

At Cube Hub, we model a fixed-price project that guarantees a fixed budget for the project, regardless of the time and expense. The main advantage of a fixed price model is that it allows the client to plan and set an exact budget. We identify the key milestones, define each milestone in more detail, get feedback and approval from stakeholders, assign each milestone to our team members assigned to the project, and visualize project phases using a Gantt chart.

SOWS EXECUTED FOR OUR CLIENTS

Cube Hub has worked with its clients to develop the software solutions for the pricing optimization initiatives. Pricing optimization would equip markets to make pricing decisions that achieve their pricing goals.

DATA SCIENCE & PRICING ANALYTICS

The end-to-end pipeline of Data, Modeling, Decisioning and Deployment, when integrated and applied in specific business decision context, delivered clear and measurable impact both on revenue and cost.

Predictive Analytics – Leveraged structured & unstructured data to predict future events, e.g., trends, pricing decisions, fraud risk, customer attrition, etc.

Optimization – Achieved optimal revenue, margin/cost in each decision framework – maximized marketing reach, resource optimization and inventory management.

Deep Learning/Artificial Intelligence – New age algorithms to derive value from complex and big data – real-time bidding, IoT sensor data-based maintenance, recommender systems.

MARKETING ANALYTICS

Customer Insights

- Pricing & Promotions

- Survey Analytics

- Path To Purchase

- Choice Modeling

- Brand Switching

Omnichannel Marketing

- Market Mix Models

- Audience Targeting

- Campaign Optimization

- Attribution Modeling

- Real-time Bidding

- A/B Testing

Product & Market Analytics

- Personalization

- Pipeline Forecasting

- Market Segmentation

- Brand Equity Analytics

- New Product Introduction

- Product Portfolio Optimization

- Merchandizing & Assortment

OPERATIONS & PLANNING

Operations Analytics

- IoT & Sensor Analytics

- Predictive Maintenance

- Resource Optimization

- Contact Center Analytics

- Store Operations Analytics

- Fraud Analytics

Supply Chain Analytics

- Demand Forecasting

- Sales and Shipments Forecasting

- Inventory Management

- Geo-spatial Analysis

- Network Planning

- Fleet and Logistics

People Analytics

- Labor Optimization

- Workforce Planning

- Sales Force Mapping

- Learning Effectiveness

- Employee Lifecycle

- Product Portfolio Optimization

RISK ANALYTICS

Supply Chain Analytics

- Financial Risk

- Operations Risk

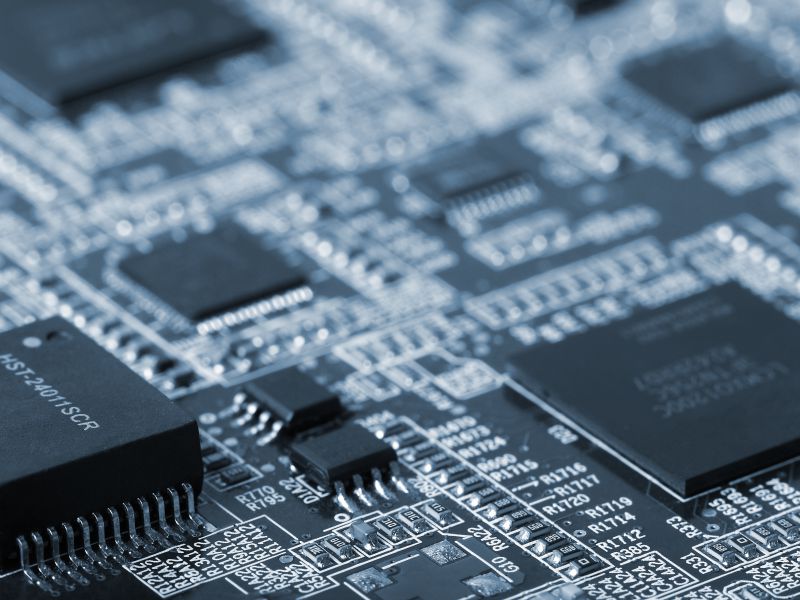

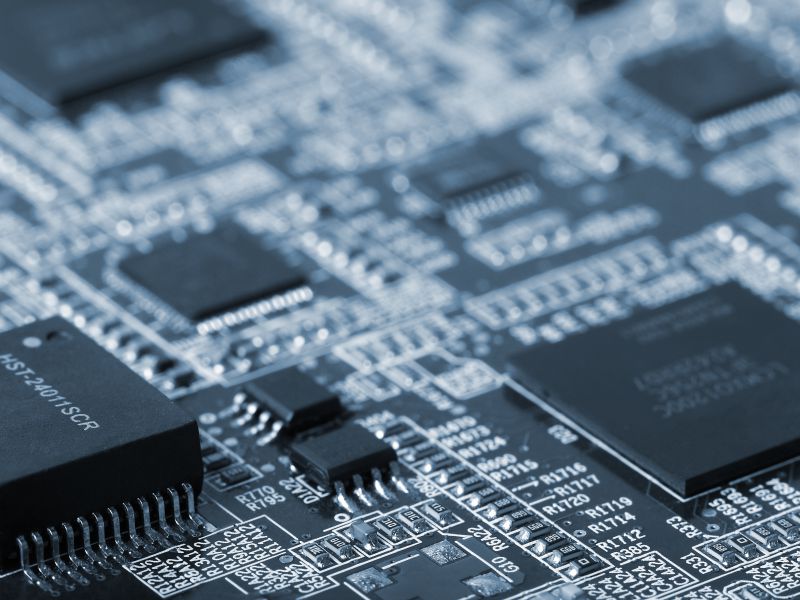

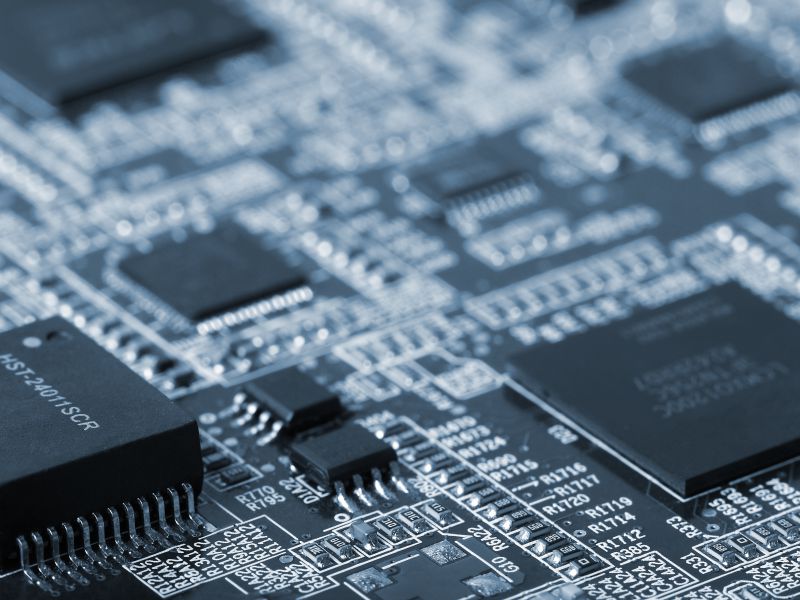

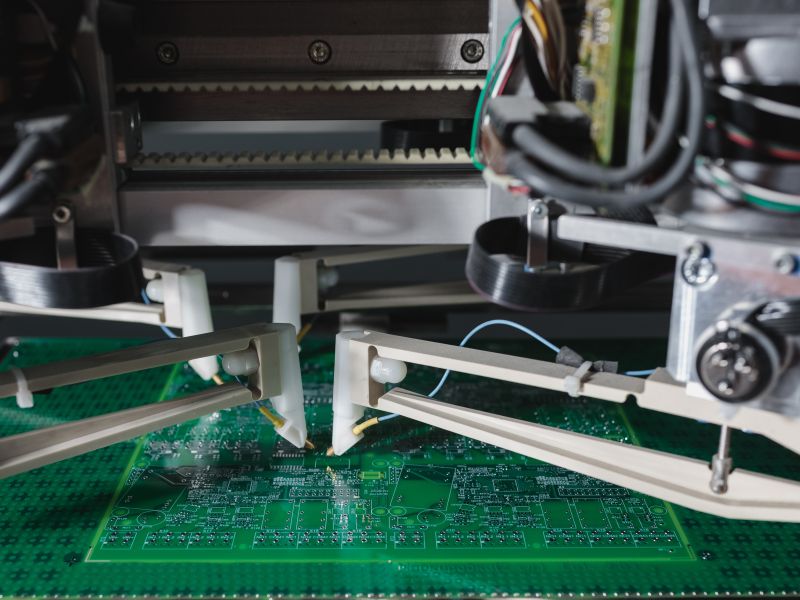

Cube Hub has executed multiple Metrology projects in the Semiconductor space. We have an excellent technical background with capabilities to support and sustain process technologies assisting in the development process at the Wafer Assembly of our semiconductor clients to meet quality, reliability, cost, yield, productivity, and manufacturability requirements.

The Metrology team has performed Metrology-related tasks to support experimental testing, research work, and defect excursion resolution.

Wafer Metrology tools are used to design and manufacture ICs by carefully controlling the film

properties, line widths, and potential defect levels in order to optimize the manufacturing

process of these devices.

These positions required working in Compressed Shifts for our 20+ member staff to support a

12 hrs per shift, 24X7, 365 days development environment.

Our team members have been working in a Cleanroom environment and meeting all regulations.

This is to ensure that the number concentration of airborne particles is controlled, and

classified, and is designed, constructed, and operated in a manner to control the introduction, generation, and retention of particles inside the room. This is to ensure contamination, air velocity, pressure, temperature, and humidity are controlled under rigid specifications.

TASKS

- Image Review and die loss taking.

- Metrology inspections.

- Coordination and submission of Failure Analysis request.

- Respond to real-time process excursions, containing material and completing documentation with details to publish to factory stakeholders.

- Highly matrixed environment interfacing with multiple development groups.

- Identifying areas of improvement in quality, reliability, cost, yield, process

stability/capability, productivity, safety, and/or ergonomics. - Statistical Process Control (SPC).

PRIMARY METRO RESPONSIBILITIES

- Efficient independent lot processing through metro operations that inspect wafer and die quality via microscope, sonar, and x-ray inspection.

- Prioritization between metro shifts, engineering, and Management.

- Support processing WIP in and out via the SC on Metrology tools.

- Escalate problems/issues to appropriate parties regarding lots, tools, safety, or disputes.

- Prompt adjustments to lot processing, from online or offline or pivot work to different tools, when sharing tool time with engineering.

- Read and understand new operations, operation changes, and product changes when necessary while following POR.

METROLOGY PROCESSES

- Optical Microscope: Image Sampling using visible or ultraviolet light to provide information about morphology and surface features.

- Electron Microscope: Uses beams of electrons to image samples at high magnification.

- X-ray diffraction: Analyzes crystal structure.

- Spectroscopy: Measures band gap, carrier concentration, and mobility of electric properties.

- Worked with the design team to understand the design intent and bring up the verification plans and schedules.

- Developed UVM test environment, test plan, and test cases based on design specification and verification requirements.

- Initiated test plan review and verification reviews with the teams at every stage.

- Debugged test cases and reported verification results to achieve the expected code/functional coverage goal.

- Cooperated with cross-functional teams and coordinated priorities to achieve higher

productivity. - Execute block level verification.

- Technology: System Verilog/UVM

ASIC Design

- Design silicon, part of a complete SOC solution. ASIC design and micro-architecture providing ASIC design implementation specifications, Functional validation, and low power optimization techniques to achieve best-in-class ASIC design, assess risks & identify issues and solutions to timely and efficiently achieve goals and project objectives

while maintaining

quality standards. Worked on client architecture: MMU, Cache, Virtualization, and high-speed standards such as PCIe, KTI/QPI/UPI. - Technology: SOC, ASIC, Verilog

- Developed complex random verification environment using System Verilog/UVM

- Writing and execution of a detailed verification test plan.

- Scripts using Python/Perl and EDA Verification tools.

- PCI Express Verification, ARM processor-based subsystem verification.

- AMBA protocols and interconnects

- On-boarded protocols like I2C/PMBUS.

- Full chip Verification, Gate Level Simulations

- Technology: System Verilog/UVM, Python

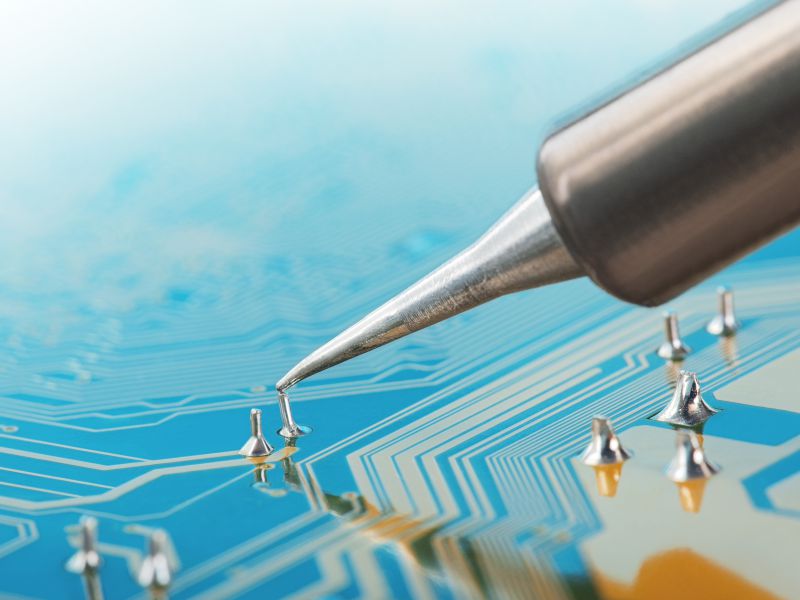

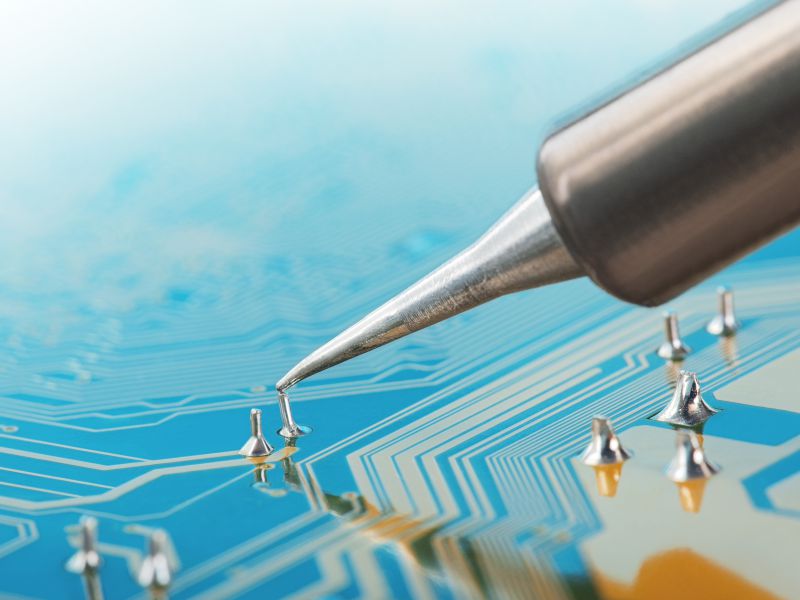

- Assembled electrical and electronic systems & prototypes using hand tools and measuring instruments.

- Installed and maintained electrical control systems and solid-state equipment.

- Modified electrical prototypes, parts, assemblies, and systems to correct functional deviations.

- Set up and operate test equipment to evaluate the performance of developmental parts, assemblies, or systems under simulated operating conditions, and record results.

- Assembled and configured server processor test platforms with the processor, heatsinks, memory DIMMs, SSD, PCIe HBA and network interface cards, and other components.

- Loaded operating system and CPLD, FLASH devices, power controllers, and clock device images both in circuit and throughout band fixtures.

- Used multimeters to make circuit measurements.

- Established remote connections over the network through terminal servers and switches.

- Configured test programs per test plans and launch and monitor test execution.

- Maintained test logs and wrote reports stored in shared directory spaces.

- Organized and maintained stock of test samples and test platforms.

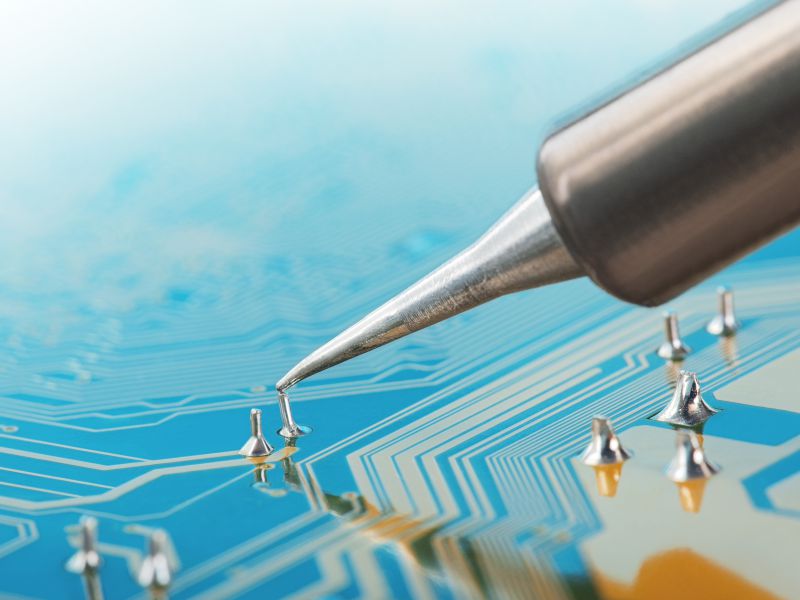

- Reworked fine pitch components with hot air and contact soldering tools.

- Technology: Multimeter, Test, Soldering

- Worked on the bugs, JIRAs, Enhancements

- Performed Log Analysis, Unit Testing

- Investigated patches for release & build management.

- Executed Google-verified stability tests – CTS, CTS verifier, GTS, MTBF, Stability KPI.

- Executed manual tests to validate the platforms.

- Worked with the Development team back and forth to make sure the change requests

are followed through. - Tabulated results with sufficient information and generated reports to summarize each run.

- Technology: Testing

- Contribution to Android product development.

- Worked on various Mobile components, take ownership of the issues reported and drive them to closure.

- Integration of platform releases with product software code.

- Troubleshoot various crashes that are reported on the development devices, debug, and fix the issues.

- Analyzed stability issues that are reported. Performed initial analysis.

- Debugged various firmware issues that are being reported, using HW debug tools such as JTAG and LAUTERBACH

- Worked with the cross-functional teams, Analyze the logs and handover the issues effectively.

- Documented software specifications, designed and develop software, create test plans, validate software, & deploy high-quality end products with release plans & software usage specifications.

- Technology: Android

PLATFORM VALIDATION, VERIFICATION & TESTING

- Worked on the bugs, JIRAs, Enhancements

- Performed Log Analysis, Unit Testing

- Investigated patches for release & build management.

- Executed Google verified stability tests – CTS, CTS verifier, GTS, MTBF, Stability KPI.

- Executed manual tests to validate the platforms.

- Worked with the Development team back and forth to make sure the change requests are followed through.

- Tabulated results with sufficient information and generated reports to summarize each run.

- Technology: Testing

- Defined and scoped design requirements and develop specifications for testing a given IP on a test chip to be implemented in RTL. ARM-based SoC, including AXI/ACE and APB bus protocols, HDL design with Verilog/System Verilog, ASIC and/or SoC design flows, and methodology including CPF/UPF flows. Experience with industry-standard RTL design, simulation, and formal verification tools. Scripting was done in Perl/TCL.

- Technology: Verilog/System Verilog, ASIC, Perl/TCL

FPGA Configuration

- Developed a software tool that can generate a bitstream for FPGA devices based on the user design.

- Sorted out dependencies in the software toolchain.

- Worked with cross teams (Marketing & Verification) to verify the tool and its output, facilitating the tapping points in the software and fetching necessary debug information.

- Worked with Silicon Engineering teams to make sure the configuration circuitry written in System Verilog is in the right format and can be consumed by the software.

- Put RTL liners in place to gate the hardware releases.

- Technology: FPGA, Python, C++

- Penetration testing and security assessment tools like Burp Suite, Wireshark, Drozer, Nmap etc

- Develop in-house tools using an interpreted programming language like Perl, Ruby, PHP,

Python etc. - Operating systems internals, UNIX, and TCP/ IP fundamentals

- Work effectively in situations involving uncertainty or lack of information and respond.

- Drive processes and systems to support the success of Clients’ products.

- Technology: Perl, Python, Burp Suite, Wireshark, Drozer, Nmap

VALIDATION & TESTING

- Mobile device testing, and application testing including LTE or UMTS technology. Carrier Validation (AT&T, TMO, and EMARA). Test automation using Python Supported the Platform layer for the Cisco Nexus family of switches. Worked on L2/L3 protocols MPLS, SR and worked on Online diagnostics for the Catalyst 6500 Switch. Work was done using C/C++, Python, Linux, and Cisco IOS/NXOS.

- Technology: C/C++, Python, Linux

MOBILE VALIDATION TESTING

- Automation/Validation Support to Clients in the areas of Android System Validation, Functional, UI, and non-functional tests, feature and regression tests, field testing, Power/KPI/Stability automated and manual testing.

- Technology: Python

- Provided overall test support for Client’s Service Center solution, which includes Client-Service Client, the corresponding Remote Software Download (RSD) Server, Handset (phone or tablet) drivers, and the handset software that is updated using this solution.

- Test planning, test case development, test execution, and result reporting High-level log analysis, top issues identification, root cause analysis, and enhancement

recommendations - Set up server update ‘recipes’ of handset software for test execution Generated metrics reports (charts) from server update data Support Product Feature testing, Regression, KPI support, Product stress stability.

- Technology: LTE, UMTS

TCM (Technology Change Management) Project Synopsis: Change Management Leads

leveraged their leadership and expertise to ensure one of our semiconductor clients

successfully drives change, adopted and delivered results for their partner product management and/or other initiatives.

BPM (Business Process Management) – Establishing a framework for business process

management in the organization including framework setup and education, assessment of top

processes (as assumed by mitigating legal risk and/or high partner value impact), prioritizing processes to drive maturity higher, and documenting those areas. Centralizing or common document repository or change management formalized for processes. Identify document

repository and change management tool. Jira Cloud and associated plugins are being used to

assess.

RESPONSIBILITIES INCLUDED

Implement a strong operating model for delivering capability changes to our partners and ensuring the program teams have partner readiness reviews prior to launch.

- Engaged with and coached program and product managers on change management

activities including but not limited to change strategy development, stakeholder analysis, and change impact assessments, sustaining plans, and effective measures for change management to support success. - Utilized industry best practices for change management and continually learn and apply into the organization and engage with Client communities of practice.

- Drove effective communication with stakeholders with each capability deployment or business value change.

- Ensured privacy and other compliance requirements are covered in change management planning.

- Action plan road map for quality delivery and processed Pain point analysis.

SKILLS

- TCM Acumen: Led large-scale, multi-organizational change including assessing issues in the context of an organization’s processes, structures, and capabilities to develop holistic organization responses.

- Stakeholder Management: The team had excellent engagement skills with an ability to collaborate with all key stakeholders.

- Communication: Strong communication and presentation skills with the ability to influence while demonstrating executive presence and good judgment

- Customer Knowledge: Lead with customer-first thinking and a general understanding of partner roles.

- Tolerance for Ambiguity: Navigated and developed a path in the face of a fast-paced changing environment that may include unpredictability, conflicting directions, and multiple demands.

- Assessed the current state of transition management, and communication processes, tools and templates.

- Developed roadmap of actions to move orgs maturity for TCM

- Began to build out of TCM toolkit to be used by change owners.

- Developed TCM plan including,

- Complete audience assessment

- Determine internal and external (customer) stakeholder communication plan

- Change impact assessments

Cube Hub has executed multiple Metrology projects in the Semiconductor space. We have an excellent technical background with capabilities to support and sustain process technologies assisting in the development process at the Wafer Assembly of our semiconductor clients to meet quality, reliability, cost, yield, productivity, and manufacturability requirements.

The Metrology team has performed Metrology-related tasks to support experimental testing, research work, and defect excursion resolution.

Wafer Metrology tools are used to design and manufacture ICs by carefully controlling the film properties, line widths, and potential defect levels in order to optimize the manufacturing process of these devices.

These positions required working in Compressed Shifts for our 20+ member staff to support a 12 hrs per shift, 24X7, 365 days development environment.

Our team members have been working in a Cleanroom environment and meeting all regulations. This is to ensure that the number concentration of airborne particles is controlled, and classified, and is designed, constructed, and operated in a manner to control the introduction, generation, and retention of particles inside the room. This is to ensure contamination, air velocity, pressure, temperature, and humidity are controlled under rigid specifications.TASKS

- Image Review and die loss taking.

- Metrology inspections.

- Coordination and submission of Failure Analysis request.

- Respond to real-time process excursions, containing material and completing documentation with details to publish to factory stakeholders.

- Highly matrixed environment interfacing with multiple development groups.

- Identifying areas of improvement in quality, reliability, cost, yield, process stability/capability, productivity, safety, and/or ergonomics.

- Statistical Process Control (SPC).

PRIMARY METRO RESPONSIBILITIES

- Efficient independent lot processing through metro operations that inspect wafer and die quality via microscope, sonar, and x-ray inspection.

- Prioritization between metro shifts, engineering, and Management.

- Support processing WIP in and out via the SC on Metrology tools.

- Escalate problems/issues to appropriate parties regarding lots, tools, safety, or disputes.

- Prompt adjustments to lot processing, from online or offline or pivot work to different tools, when sharing tool time with engineering.

- Read and understand new operations, operation changes, and product changes when necessary while following POR.

METROLOGY PROCESSES

- Optical Microscope: Image Sampling using visible or ultraviolet light to provide information about morphology and surface features.

- Electron Microscope: Uses beams of electrons to image samples at high magnification.

- X-ray diffraction: Analyzes crystal structure.

- Spectroscopy: Measures band gap, carrier concentration, and mobility of electric properties.

- Worked with the design team to understand the design intent and bring up the verification plans and schedules.

- Developed UVM test environment, test plan, and test cases based on design specification and verification requirements.

- Initiated test plan review and verification reviews with the teams at every stage.

- Debugged test cases and reported verification results to achieve the expected code/functional coverage goal.

- Cooperated with cross-functional teams and coordinated priorities to achieve higher productivity.

- Execute block level verification.

- Technology: System Verilog/UVM

ASIC Design

- Design silicon, part of a complete SOC solution. ASIC design and micro-architecture providing ASIC design implementation specifications, Functional validation, and low power optimization techniques to achieve best-in-class ASIC design, assess risks & identify issues and solutions to timely and efficiently achieve goals and project objectives while maintaining quality standards. Worked on client architecture: MMU, Cache, Virtualization, and high-speed standards such as PCIe, KTI/QPI/UPI.

- Technology: SOC, ASIC, Verilog

- Developed complex random verification environment using System Verilog/UVM

- Writing and execution of a detailed verification test plan.

- Scripts using Python/Perl and EDA Verification tools.

- PCI Express Verification, ARM processor-based subsystem verification.

- AMBA protocols and interconnects

- On-boarded protocols like I2C/PMBUS.

- Full chip Verification, Gate Level Simulations

- Technology: System Verilog/UVM, Python

- Assembled electrical and electronic systems & prototypes using hand tools and measuring instruments.

- Installed and maintained electrical control systems and solid-state equipment.

- Modified electrical prototypes, parts, assemblies, and systems to correct functional deviations.

- Set up and operate test equipment to evaluate the performance of developmental parts, assemblies, or systems under simulated operating conditions, and record results.

- Assembled and configured server processor test platforms with the processor, heatsinks, memory DIMMs, SSD, PCIe HBA and network interface cards, and other components.

- Loaded operating system and CPLD, FLASH devices, power controllers, and clock device images both in circuit and throughout band fixtures.

- Used multimeters to make circuit measurements.

- Established remote connections over the network through terminal servers and switches.

- Configured test programs per test plans and launch and monitor test execution.

- Maintained test logs and wrote reports stored in shared directory spaces.

- Organized and maintained stock of test samples and test platforms.

- Reworked fine pitch components with hot air and contact soldering tools.

- Technology: Multimeter, Test, Soldering

- Worked on the bugs, JIRAs, Enhancements

- Performed Log Analysis, Unit Testing

- Investigated patches for release & build management.

- Executed Google-verified stability tests – CTS, CTS verifier, GTS, MTBF, Stability KPI.

- Executed manual tests to validate the platforms.

- Worked with the Development team back and forth to make sure the change requests

are followed through. - Tabulated results with sufficient information and generated reports to summarize each run.

- Technology: Testing

- Contribution to Android product development.

- Worked on various Mobile components, take ownership of the issues reported and drive them to closure.

- Integration of platform releases with product software code.

- Troubleshoot various crashes that are reported on the development devices, debug, and fix the issues.

- Analyzed stability issues that are reported. Performed initial analysis.

- Debugged various firmware issues that are being reported, using HW debug tools such as JTAG and LAUTERBACH

- Worked with the cross-functional teams, Analyze the logs and handover the issues effectively.

- Documented software specifications, designed and develop software, create test plans, validate software, & deploy high-quality end products with release plans & software usage specifications.

- Technology: Android

PLATFORM VALIDATION, VERIFICATION & TESTING

- Worked on the bugs, JIRAs, Enhancements

- Performed Log Analysis, Unit Testing

- Investigated patches for release & build management.

- Executed Google verified stability tests – CTS, CTS verifier, GTS, MTBF, Stability KPI.

- Executed manual tests to validate the platforms.

- Worked with the Development team back and forth to make sure the change requests are followed through.

- Tabulated results with sufficient information and generated reports to summarize each run.

- Technology: Testing

- Defined and scoped design requirements and develop specifications for testing a given IP on a test chip to be implemented in RTL. ARM-based SoC, including AXI/ACE and APB bus protocols, HDL design with Verilog/System Verilog, ASIC and/or SoC design flows, and methodology including CPF/UPF flows. Experience with industry-standard RTL design, simulation, and formal verification tools. Scripting was done in Perl/TCL.

- Technology: Verilog/System Verilog, ASIC, Perl/TCL

FPGA Configuration

- Developed a software tool that can generate a bitstream for FPGA devices based on the user design.

- Sorted out dependencies in the software toolchain.

- Worked with cross teams (Marketing & Verification) to verify the tool and its output, facilitating the tapping points in the software and fetching necessary debug information.

- Worked with Silicon Engineering teams to make sure the configuration circuitry written in System Verilog is in the right format and can be consumed by the software.

- Put RTL liners in place to gate the hardware releases.

- Technology: FPGA, Python, C++

- Penetration testing and security assessment tools like Burp Suite, Wireshark, Drozer, Nmap etc

- Develop in-house tools using an interpreted programming language like Perl, Ruby, PHP,

Python etc. - Operating systems internals, UNIX, and TCP/ IP fundamentals

- Work effectively in situations involving uncertainty or lack of information and respond.

- Drive processes and systems to support the success of Clients’ products.

- Technology: Perl, Python, Burp Suite, Wireshark, Drozer, Nmap

VALIDATION & TESTING

- Mobile device testing, and application testing including LTE or UMTS technology. Carrier Validation (AT&T, TMO, and EMARA). Test automation using Python Supported the Platform layer for the Cisco Nexus family of switches. Worked on L2/L3 protocols MPLS, SR and worked on Online diagnostics for the Catalyst 6500 Switch. Work was done using C/C++, Python, Linux, and Cisco IOS/NXOS.

- Technology: C/C++, Python, Linux

MOBILE VALIDATION TESTING

- Automation/Validation Support to Clients in the areas of Android System Validation, Functional, UI, and non-functional tests, feature and regression tests, field testing, Power/KPI/Stability automated and manual testing.

- Technology: Python

- Provided overall test support for Client’s Service Center solution, which includes Client-Service Client, the corresponding Remote Software Download (RSD) Server, Handset (phone or tablet) drivers, and the handset software that is updated using this solution.

- Test planning, test case development, test execution, and result reporting High-level log analysis, top issues identification, root cause analysis, and enhancement

recommendations - Set up server update ‘recipes’ of handset software for test execution Generated metrics reports (charts) from server update data Support Product Feature testing, Regression, KPI support, Product stress stability.

- Technology: LTE, UMTS

TCM (Technology Change Management) Project Synopsis: Change Management Leads leveraged their leadership and expertise to ensure one of our semiconductor clients successfully drives change, adopted and delivered results for their partner product management and/or other initiatives.

BPM (Business Process Management) – Establishing a framework for business process management in the organization including framework setup and education, assessment of top processes (as assumed by mitigating legal risk and/or high partner value impact), prioritizing processes to drive maturity higher, and documenting those areas. Centralizing or common document repository or change management formalized for processes. Identify document repository and change management tool. Jira Cloud and associated plugins are being used to assess.RESPONSIBILITIES INCLUDED

Implement a strong operating model for delivering capability changes to our partners and ensuring the program teams have partner readiness reviews prior to launch.

- Engaged with and coached program and product managers on change management activities including but not limited to change strategy development, stakeholder analysis, and change impact assessments, sustaining plans, and effective measures for change management to support success.

- Utilized industry best practices for change management and continually learn and apply into the organization and engage with Client communities of practice.

- Drove effective communication with stakeholders with each capability deployment or business value change.

- Ensured privacy and other compliance requirements are covered in change management planning.

- Action plan road map for quality delivery and processed Pain point analysis.

SKILLS

- TCM Acumen: Led large-scale, multi-organizational change including assessing issues in the context of an organization’s processes, structures, and capabilities to develop holistic organization responses.

- Stakeholder Management: The team had excellent engagement skills with an ability to collaborate with all key stakeholders.

- Communication: Strong communication and presentation skills with the ability to influence while demonstrating executive presence and good judgment

- Customer Knowledge: Lead with customer-first thinking and a general understanding of partner roles.

- Tolerance for Ambiguity: Navigated and developed a path in the face of a fast-paced changing environment that may include unpredictability, conflicting directions, and multiple demands.

- Assessed the current state of transition management, and communication processes, tools and templates.

- Developed roadmap of actions to move orgs maturity for TCM

- Began to build out of TCM toolkit to be used by change owners.

- Developed TCM plan including,

-

- Complete audience assessment

- Determine internal and external (customer) stakeholder communication plan

- Change impact assessments

-

Cube Hub has worked with its clients to develop the software solutions for the pricing optimization initiatives. Pricing optimization would equip markets to make pricing decisions that achieve their pricing goals.

DATA SCIENCE & PRICING ANALYTICS

The end-to-end pipeline of Data, Modeling, Decisioning and Deployment, when integrated and applied in specific business decision context, delivered clear and measurable impact both on revenue and cost.

Predictive Analytics – Leveraged structured & unstructured data to predict future events, e.g., trends, pricing decisions, fraud risk, customer attrition, etc.

Optimization – Achieved optimal revenue, margin/cost in each decision framework – maximized marketing reach, resource optimization and inventory management.

Deep Learning/Artificial Intelligence – New age algorithms to derive value from complex and big data – real-time bidding, IoT sensor data-based maintenance, recommender systems.

MARKETING ANALYTICS

Customer Insights

- Pricing & Promotions

- Survey Analytics

- Path To Purchase

- Choice Modeling

- Brand Switching

Omnichannel Marketing

- Market Mix Models

- Audience Targeting

- Campaign Optimization

- Attribution Modeling

- Real-time Bidding

- A/B Testing

Product & Market Analytics

- Personalization

- Pipeline Forecasting

- Market Segmentation

- Brand Equity Analytics

- New Product Introduction

- Product Portfolio Optimization

- Merchandizing & Assortment

OPERATIONS & PLANNING

Operations Analytics

- IoT & Sensor Analytics

- Predictive Maintenance

- Resource Optimization

- Contact Center Analytics

- Store Operations Analytics

- Fraud Analytics

Supply Chain Analytics

- Demand Forecasting

- Sales and Shipments Forecasting

- Inventory Management

- Geo-spatial Analysis

- Network Planning

- Fleet and Logistics

People Analytics

- Labor Optimization

- Workforce Planning

- Sales Force Mapping

- Learning Effectiveness

- Employee Lifecycle

- Product Portfolio Optimization

RISK ANALYTICS

Supply Chain Analytics

- Financial Risk

- Operations Risk

Cube Hub has executed multiple Metrology projects in the Semiconductor space. We have an excellent technical background with capabilities to support and sustain process technologies assisting in the development process at the Wafer Assembly of our semiconductor clients to meet quality, reliability, cost, yield, productivity, and manufacturability requirements.

The Metrology team has performed Metrology-related tasks to support experimental testing, research work, and defect excursion resolution.

Wafer Metrology tools are used to design and manufacture ICs by carefully controlling the film properties, line widths, and potential defect levels in order to optimize the manufacturing process of these devices.

These positions required working in Compressed Shifts for our 20+ member staff to support a 12 hrs per shift, 24X7, 365 days development environment.

Our team members have been working in a Cleanroom environment and meeting all regulations.This is to ensure that the number concentration of airborne particles is controlled, and classified, and is designed, constructed, and operated in a manner to control the introduction, generation, and retention of particles inside the room. This is to ensure contamination, air velocity, pressure, temperature, and humidity are controlled under rigid specifications.

TASKS

- Image Review and die loss taking.

- Metrology inspections.

- Coordination and submission of Failure Analysis request.

- Respond to real-time process excursions, containing material and completing documentation with details to publish to factory stakeholders.

- Highly matrixed environment interfacing with multiple development groups.

- Identifying areas of improvement in quality, reliability, cost, yield, process stability/capability, productivity, safety, and/or ergonomics.

- Statistical Process Control (SPC).

PRIMARY METRO RESPONSIBILITIES

- Efficient independent lot processing through metro operations that inspect wafer and die quality via microscope, sonar, and x-ray inspection.

- Prioritization between metro shifts, engineering, and Management.

- Support processing WIP in and out via the SC on Metrology tools.

- Escalate problems/issues to appropriate parties regarding lots, tools, safety, or disputes.

- Prompt adjustments to lot processing, from online or offline or pivot work to different tools, when sharing tool time with engineering.

- Read and understand new operations, operation changes, and product changes when necessary while following POR.

METROLOGY PROCESSES

- Optical Microscope: Image Sampling using visible or ultraviolet light to provide information about morphology and surface features.

- Electron Microscope: Uses beams of electrons to image samples at high magnification.

- X-ray diffraction: Analyzes crystal structure.

- Spectroscopy: Measures band gap, carrier concentration, and mobility of electric properties.

- Worked with the design team to understand the design intent and bring up the verification plans and schedules.

- Developed UVM test environment, test plan, and test cases based on design specification and verification requirements.

- Initiated test plan review and verification reviews with the teams at every stage.

- Debugged test cases and reported verification results to achieve the expected code/functional coverage goal.

- Cooperated with cross-functional teams and coordinated priorities to achieve higher productivity.

- Execute block level verification.

- Technology: System Verilog/UVM

ASIC Design

- Design silicon, part of a complete SOC solution. ASIC design and micro-architecture providing ASIC design implementation specifications, Functional validation, and low power optimization techniques to achieve best-in-class ASIC design, assess risks & identify issues and solutions to timely and efficiently achieve goals and project objectives while maintaining quality standards. Worked on client architecture: MMU, Cache, Virtualization, and high-speed standards such as PCIe, KTI/QPI/UPI.

- Technology: SOC, ASIC, Verilog

- Developed complex random verification environment using System Verilog/UVM

- Writing and execution of a detailed verification test plan.

- Scripts using Python/Perl and EDA Verification tools.

- PCI Express Verification, ARM processor-based subsystem verification.

- AMBA protocols and interconnects

- On-boarded protocols like I2C/PMBUS.

- Full chip Verification, Gate Level Simulations

- Technology: System Verilog/UVM, Python

- Assembled electrical and electronic systems & prototypes using hand tools and measuring instruments.

- Installed and maintained electrical control systems and solid-state equipment.

- Modified electrical prototypes, parts, assemblies, and systems to correct functional deviations.

- Set up and operate test equipment to evaluate the performance of developmental parts, assemblies, or systems under simulated operating conditions, and record results.

- Assembled and configured server processor test platforms with the processor, heatsinks, memory DIMMs, SSD, PCIe HBA and network interface cards, and other components.

- Loaded operating system and CPLD, FLASH devices, power controllers, and clock device images both in circuit and throughout band fixtures.

- Used multimeters to make circuit measurements.

- Established remote connections over the network through terminal servers and switches.

- Configured test programs per test plans and launch and monitor test execution.

- Maintained test logs and wrote reports stored in shared directory spaces.

- Organized and maintained stock of test samples and test platforms.

- Reworked fine pitch components with hot air and contact soldering tools.

- Technology: Multimeter, Test, Soldering

- Worked on the bugs, JIRAs, Enhancements

- Performed Log Analysis, Unit Testing

- Investigated patches for release & build management.

- Executed Google-verified stability tests – CTS, CTS verifier, GTS, MTBF, Stability KPI.

- Executed manual tests to validate the platforms.

- Worked with the Development team back and forth to make sure the change requests

are followed through. - Tabulated results with sufficient information and generated reports to summarize each run.

- Technology: Testing

- Contribution to Android product development.

- Worked on various Mobile components, take ownership of the issues reported and drive them to closure.

- Integration of platform releases with product software code.

- Troubleshoot various crashes that are reported on the development devices, debug, and fix the issues.

- Analyzed stability issues that are reported. Performed initial analysis.

- Debugged various firmware issues that are being reported, using HW debug tools such as JTAG and LAUTERBACH

- Worked with the cross-functional teams, Analyze the logs and handover the issues effectively.

- Documented software specifications, designed and develop software, create test plans, validate software, & deploy high-quality end products with release plans & software usage specifications.

- Technology: Android

PLATFORM VALIDATION, VERIFICATION & TESTING

- Worked on the bugs, JIRAs, Enhancements

- Performed Log Analysis, Unit Testing

- Investigated patches for release & build management.

- Executed Google verified stability tests – CTS, CTS verifier, GTS, MTBF, Stability KPI.

- Executed manual tests to validate the platforms.

- Worked with the Development team back and forth to make sure the change requests are followed through.

- Tabulated results with sufficient information and generated reports to summarize each run.

- Technology: Testing

- Defined and scoped design requirements and develop specifications for testing a given IP on a test chip to be implemented in RTL. ARM-based SoC, including AXI/ACE and APB bus protocols, HDL design with Verilog/System Verilog, ASIC and/or SoC design flows, and methodology including CPF/UPF flows. Experience with industry-standard RTL design, simulation, and formal verification tools. Scripting was done in Perl/TCL.

- Technology: Verilog/System Verilog, ASIC, Perl/TCL

FPGA Configuration

- Developed a software tool that can generate a bitstream for FPGA devices based on the user design.

- Sorted out dependencies in the software toolchain.

- Worked with cross teams (Marketing & Verification) to verify the tool and its output, facilitating the tapping points in the software and fetching necessary debug information.

- Worked with Silicon Engineering teams to make sure the configuration circuitry written in System Verilog is in the right format and can be consumed by the software.

- Put RTL liners in place to gate the hardware releases.

- Technology: FPGA, Python, C++

- Penetration testing and security assessment tools like Burp Suite, Wireshark, Drozer, Nmap etc

- Develop in-house tools using an interpreted programming language like Perl, Ruby, PHP,

Python etc. - Operating systems internals, UNIX, and TCP/ IP fundamentals

- Work effectively in situations involving uncertainty or lack of information and respond.

- Drive processes and systems to support the success of Clients’ products.

- Technology: Perl, Python, Burp Suite, Wireshark, Drozer, Nmap

VALIDATION & TESTING

- Mobile device testing, and application testing including LTE or UMTS technology. Carrier Validation (AT&T, TMO, and EMARA). Test automation using Python Supported the Platform layer for the Cisco Nexus family of switches. Worked on L2/L3 protocols MPLS, SR and worked on Online diagnostics for the Catalyst 6500 Switch. Work was done using C/C++, Python, Linux, and Cisco IOS/NXOS.

- Technology: C/C++, Python, Linux

MOBILE VALIDATION TESTING

- Automation/Validation Support to Clients in the areas of Android System Validation, Functional, UI, and non-functional tests, feature and regression tests, field testing, Power/KPI/Stability automated and manual testing.

- Technology: Python

- Provided overall test support for Client’s Service Center solution, which includes Client-Service Client, the corresponding Remote Software Download (RSD) Server, Handset (phone or tablet) drivers, and the handset software that is updated using this solution.

- Test planning, test case development, test execution, and result reporting High-level log analysis, top issues identification, root cause analysis, and enhancement

recommendations - Set up server update ‘recipes’ of handset software for test execution Generated metrics reports (charts) from server update data Support Product Feature testing, Regression, KPI support, Product stress stability.

- Technology: LTE, UMTS

TCM (Technology Change Management) Project Synopsis: Change Management Leads leveraged their leadership and expertise to ensure one of our semiconductor clients successfully drives change, adopted and delivered results for their partner product management and/or other initiatives.

BPM (Business Process Management) – Establishing a framework for business process management in the organization including framework setup and education, assessment of top processes (as assumed by mitigating legal risk and/or high partner value impact), prioritizing processes to drive maturity higher, and documenting those areas. Centralizing or common document repository or change management formalized for processes. Identify document repository and change management tool. Jira Cloud and associated plugins are being used to assess.RESPONSIBILITIES INCLUDED

Implement a strong operating model for delivering capability changes to our partners and ensuring the program teams have partner readiness reviews prior to launch.

- Engaged with and coached program and product managers on change management activities including but not limited to change strategy development, stakeholder analysis, and change impact assessments, sustaining plans, and effective measures for change management to support success.

- Utilized industry best practices for change management and continually learn and apply into the organization and engage with Client communities of practice.

- Drove effective communication with stakeholders with each capability deployment or business value change.

- Ensured privacy and other compliance requirements are covered in change management planning.

- Action plan road map for quality delivery and processed Pain point analysis.

SKILLS

- TCM Acumen: Led large-scale, multi-organizational change including assessing issues in the context of an organization’s processes, structures, and capabilities to develop holistic organization responses.

- Stakeholder Management: The team had excellent engagement skills with an ability to collaborate with all key stakeholders.

- Communication: Strong communication and presentation skills with the ability to influence while demonstrating executive presence and good judgment

- Customer Knowledge: Lead with customer-first thinking and a general understanding of partner roles.

- Tolerance for Ambiguity: Navigated and developed a path in the face of a fast-paced changing environment that may include unpredictability, conflicting directions, and multiple demands.

- Assessed the current state of transition management, and communication processes, tools and templates.

- Developed roadmap of actions to move orgs maturity for TCM

- Began to build out of TCM toolkit to be used by change owners.

- Developed TCM plan including,

-

- Complete audience assessment

- Determine internal and external (customer) stakeholder communication plan

- Change impact assessments

-